Boom for High-current Contact Elements

Schalksmühle, 2021-03-29 Lumberg has been producing customized high-current contact elements for automotive applications for more than 15 years. They are installed in millions of mechatronic modules and control units, especially in current electric vehicles. They are also recommended for use in industrial electric motors.

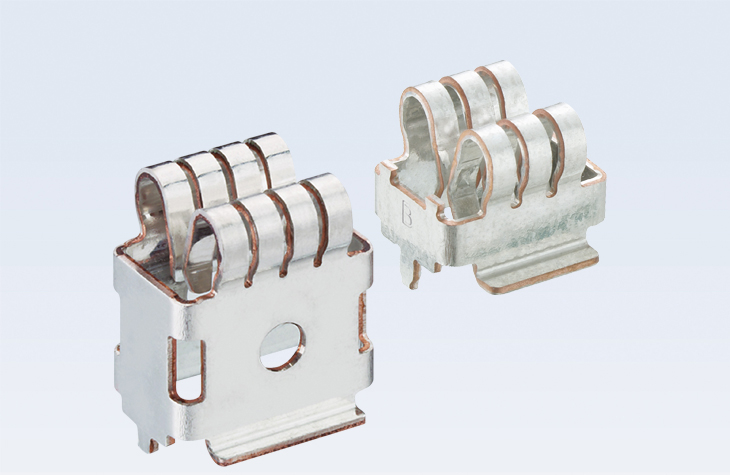

Particularly in tight spaces, the phase contacts, plugged onto standard tab contacts, optimally connect PCBs that are on top of each other. The phase contact, which is SMT-soldered onto the PCB – it can just as well be laser-welded onto a lead frame – makes vertical contact with a blade contact on the second PCB. Phase contacts with a mating area open on both sides are a special feature: Here, the tab contact can optionally be inserted from above – or through the circuit board – also from below. As a specialist for precise punching-bending contacts in high volumes, Lumberg can also easily integrate positioning pegs into the geometry for a perfect fit on the PCB.

The high-current contact sockets carry the part number 4580 at Lumberg, currently six standard contacts are available. The single-pole and tin-plated contact sockets of the smaller version 4580 03 mate with tab contacts of 5.3 mm x 0.8–1.5 mm or up to 5.3 mm x 1.5–2.0 mm. Depending on the PCB layout or the lead frame, rated currents (at Tamb 20 °C) up to 60 A with contact resistance < 0.5 mmΩ can be realized. In the larger version 4580 04, tab contacts up to 8 mm can be mated, then at rated currents up to 80 A with contact resistance < 1.0 mmΩ.

Media Contact:

Lumberg Holding GmbH & Co. KG

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Products Article as PDF Printable Photo