Celebrating 30 Years of RAST: New Allrounder for RAST 2.5 in IDT for Lumberg’s Semi-automatic Machines

Schalksmühle, 17 October 2016. Lumberg is a leading global manufacturer of so-called Raster-Anschluss-Steck-Technik – or RAST – connectors, which came onto the market exactly 30 years ago. The original RAST home appliance specifications were called to life in 1986, under the umbrella of the German Electrical and Electronic Manufacturers’ Association, the ZVEI, by a technology working group comprised of the makers of large home appliances and of connectors, with Lumberg contributing significantly toward this. Since then, the RAST connector, which is inherent in white goods – and here especially with a 2.5 mm spacing – can be found in numerous other new applications in many other business segments, all the way to automotive technology. Especially within automotive technology, the market for this continues to grow significantly.

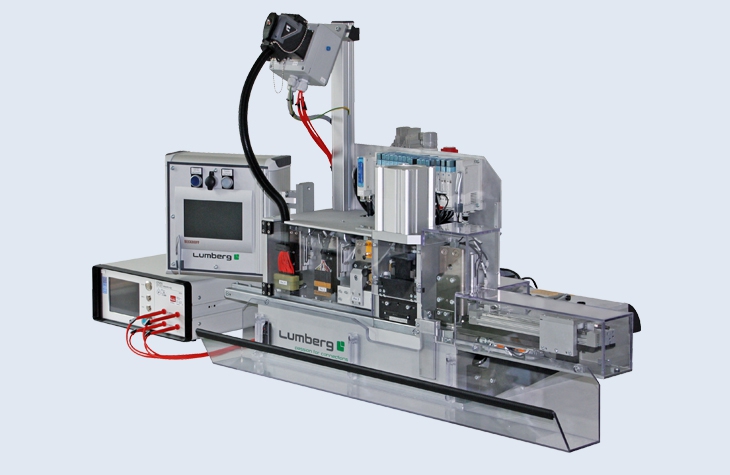

For RAST connector series, the economic efficiency of the OEM lies especially in the connection with Insulation Displacement Technology (IDT). Lumberg therefore develops, produces and markets not only connectors but also the crimping tools required to make the cable harnesses – from simple pincer to a fully-automatic VARICON 7000.

The growing popularity of RAST 2.5 connectors increases the diversity of complex cable harness configurations. The requirements in relation to flexibility and quality-assurance accessories for semi-automatic harnessing machines are equally growing. To meet these requirements, Lumberg has advanced its highly successful and proven HA35e, of which roughly 50 units are sold each year.

Now called the HA35f – f stands for flexible – the semi-automatic machine has been given a modular update to meet the assembler’s requirements. For example, the semi-automatic machine can be custom-fitted with a keying cutting station inclusive of a test of the cut keying as a modular add-on. Optionally, it is possible to read the colors of the individual conductors to be inserted manually by the machine operator. The color test naturally takes place before pressing so that misconnections can be corrected, thus avoiding cable and connector rejects. Using a high-voltage test unit, flashovers from contact to contact inside the connector (free conductor end on the opposite side) can be excluded. Linking elements on the connectors facilitate an economical cardboard packaging without costly all-round bar feeders. It is also possible to remove these linking elements using a special cutting unit as a further module. A modified cable template guide makes it easier for the operator to insert the cables, creating an even higher crimping rate.

The basic HA35f semi-automatic machine with in total five add-on modules can thus be flexibly upgraded and expanded. The add-ons are identified with the respective indices, such as CA for Color Approval, or KC for Keying Cutting.

Total no. of characters incl. blanks: 2,934

Media Contact:

Lumberg Holding GmbH & Co. KG

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Article as PDF Printable Photo