Evolution meets Revolution: Reversible Arbitrary Direct Mating with the PCB using SmartSKEDD in IDT

Schalksmühle, 12.10.2018. If the “direct connector” was previously a synonym for a connector plugged onto the edge of a printed circuit board (PCB), then learning is now required here: Lumberg introduces the direct connector for any position on the PCB. Without having to solder it and, of course, without being plugged onto a corresponding part. In addition, the connector can be plugged-in and plugged-out several times – and of course in insulation displacement technology (IDT), which allows all the advantages of automated cable assembly and thus also efficiently high quantities.

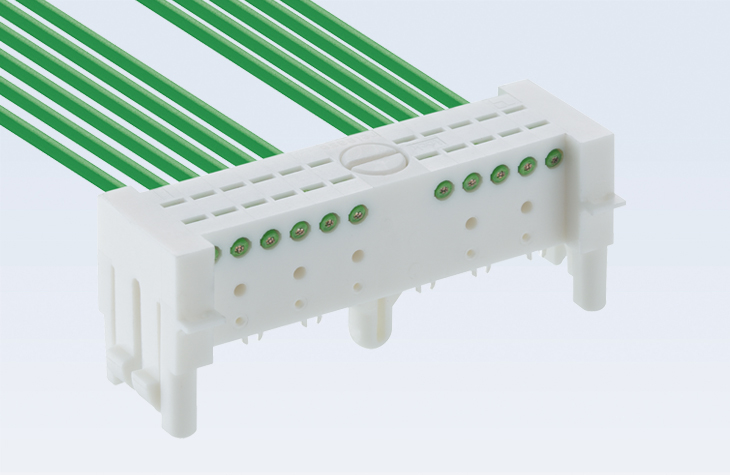

SKEDD makes this possible. The individual contact comprises two symmetrical contact tongues which, when inserted into a plated-through hole in the PCB, retract. The contact pressure forces from the two tongues then create a steadfast mechanical-electrical connection inside the hole – no need for soldering.

The connectors can mate and lock without having to use tools, for total convenience when mounting entire sub-assemblies. This empowers completely new designs since the connectors can mate right in the center of a printed circuit board. Or even on the reverse side, if the edge and surface of the printed circuit board should already be exhausted.

This technology enables the reduction of installation space and weight, an electrical interface, a contact resistance and thus a potential source of error as well as an assembly process are omitted. The thermal load of a FR4 printed circuit board caused by a soldering process or the use of additional devices for a press-fit process is also eliminated.

The Lumberg SmartSKEDD connector comes in two model versions right from the start. What both direct connectors have in common is their exceptional robustness:

Three solid pins on each housing guarantee secure positioning and prevent mismating. And there is more: each side of the connector features two snap-fits that lock the connector tightly onto the PCB. To release the connector, simply press on this primary lock.

The retaining forces are here alone roughly more than 50 N.

If a secondary lock is needed – as is the case for many applications from the business unit Automotive under LV 214 standard – or your application just needs that extra measure of retention, the second SmartSKEDD model features a pre-assembled central pin which increases the retaining force of the entire system to almost 100 N. Again, this assembly is tool-free: it is delivered and pinned in ‘lock’ position. This central pin then additionally locks into the printed circuit board and reliably secures the connector. During servicing, a simple screwdriver is then sufficient to turn the pin from the “lock” position to the “release” position. Here, reversible mating also facilitates for the first time the simple exchange of components, as is required, for example, during servicing.

Both SmartSKEDD direct connectors have a 2.5 mm pitch and come with numbers of poles from 3 – 11, in the version without pin even up to 13 poles. Designed for the temperature range from -40 to 130 °C, the housing is halogen-free in PBT V-0 according to UL94, while the copper-tin contacts are always silver-plated. The contact resistance at Tamb 20 °C is ≤ 5 mΩ, the rated voltage at 50 V AC and the rated current at 4 A (Tamb 85 °C).

Total no. of characters incl. blanks: 3.390

Media Contact:

Lumberg Holding GmbH & Co. KG

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Products Article as PDF Printable Photo