IMS Innovation

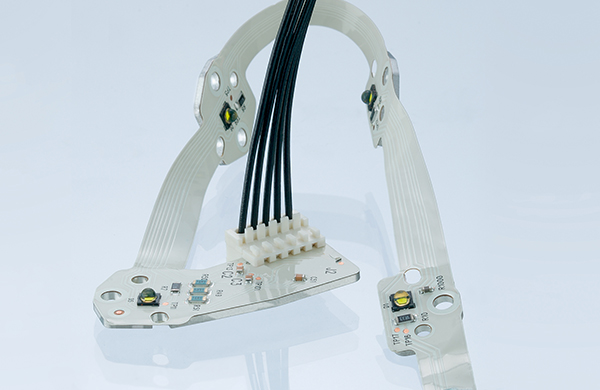

RAST 2.5-Connector for Copper and Aluminum PCBs

Automotive electronics increasingly require the heat produced from electronic components to be dissipated in order to improve the life and functionality of modern parts. Especially high-power LEDs for vehicle headlights demand an optimized heat management for tight installation spaces. Insulated Metal Substrate (IMS) is used more and more for printed circuit boards, with copper respectively aluminum being the primary thermoconductive substrate to which dielectric and copper traces are applied.

As a pioneer in the field of RAST connectors we have developed a direct connector with three to five poles that secures the safe single-sided mating with an aluminum PCB. Its mating face is oriented towards the versatile 2.5 RAST connectors whose proven record sees it used in millions of vehicles as it can be manufactured to fit operating assembly robots with lines of a diameter between 0.22 and 0.38 mm2. With nickel layer and selectively gold-plated contacts the new connectors can mate with copper resp. aluminum PCBs ranging between 1.535 mm and 1.71 mm inclusive of dielectric and copper trace.

Aluminum is used as the conductive material and mates only on one side as a result of the direct connector. This design doubles as a highly space-saving and economical solution which requires an additional lock. Varying connector types are available with different locking options or even supporting frames. For use in temperatures ranging between -40 and +130 degree Celsius and a 50 V AC rate voltage, the new connector demonstrates its versatility and convenience of application for small load currents of up to 4 Ampères.

Media Contact:

Lumberg Holding GmbH & Co. KG

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Article as PDF